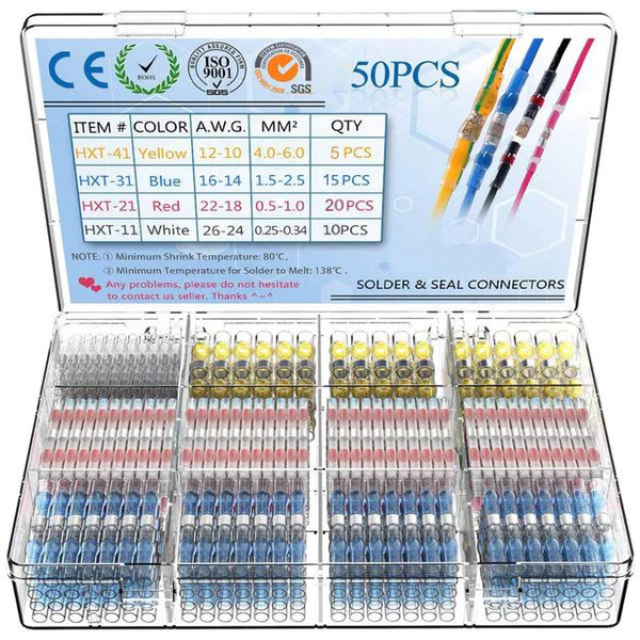

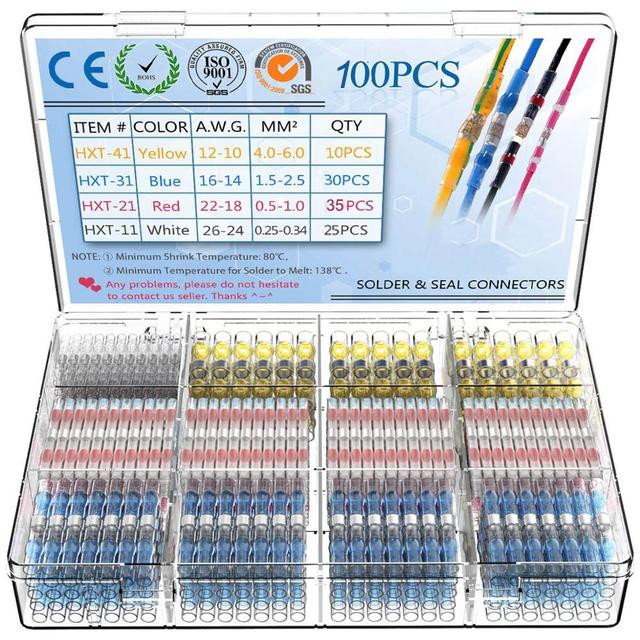

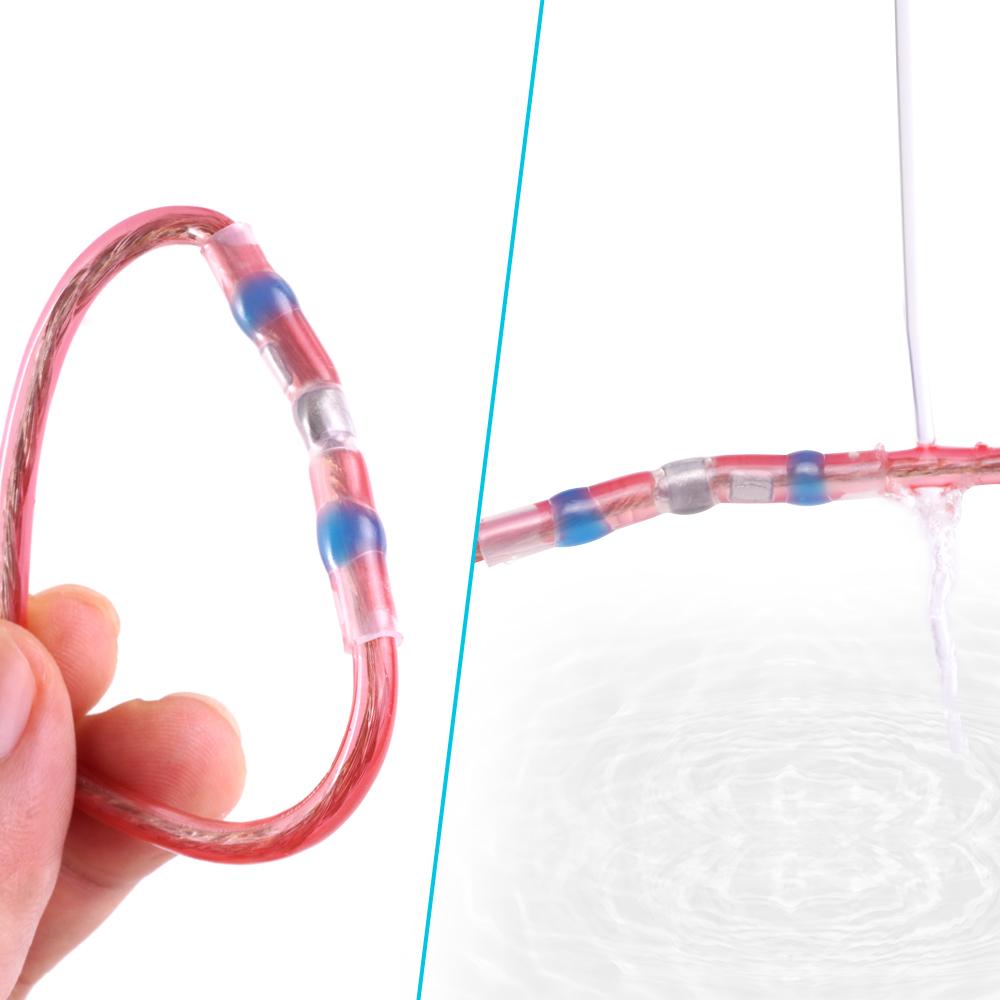

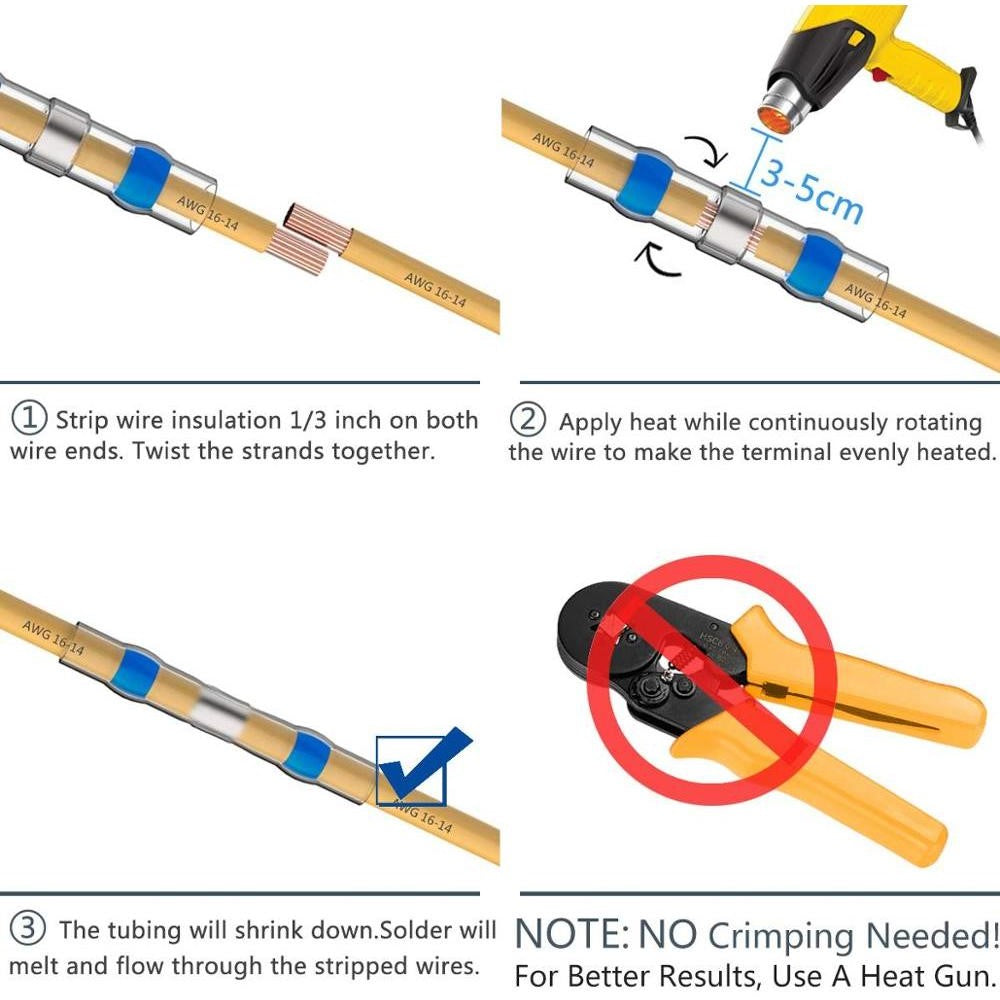

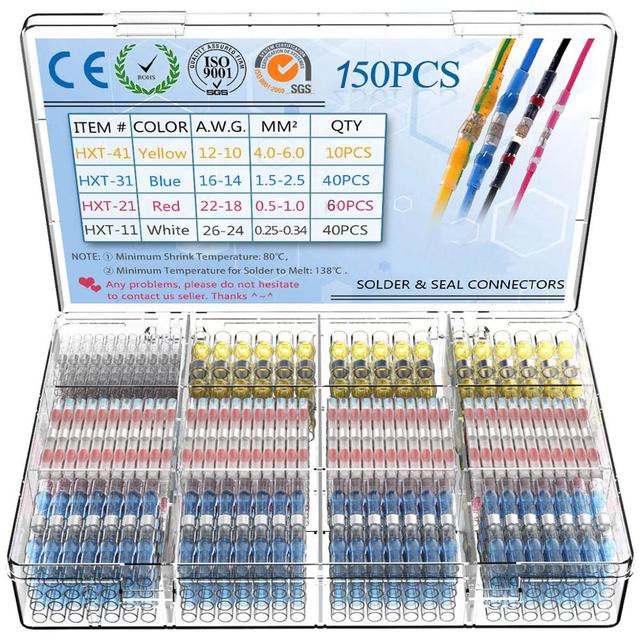

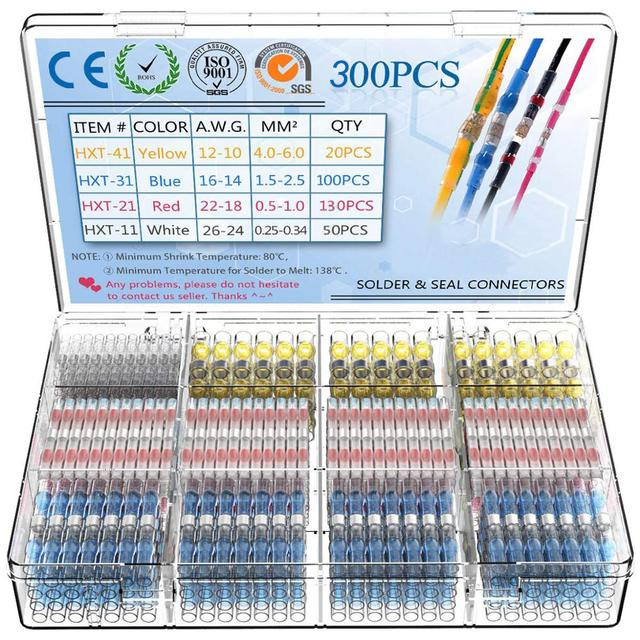

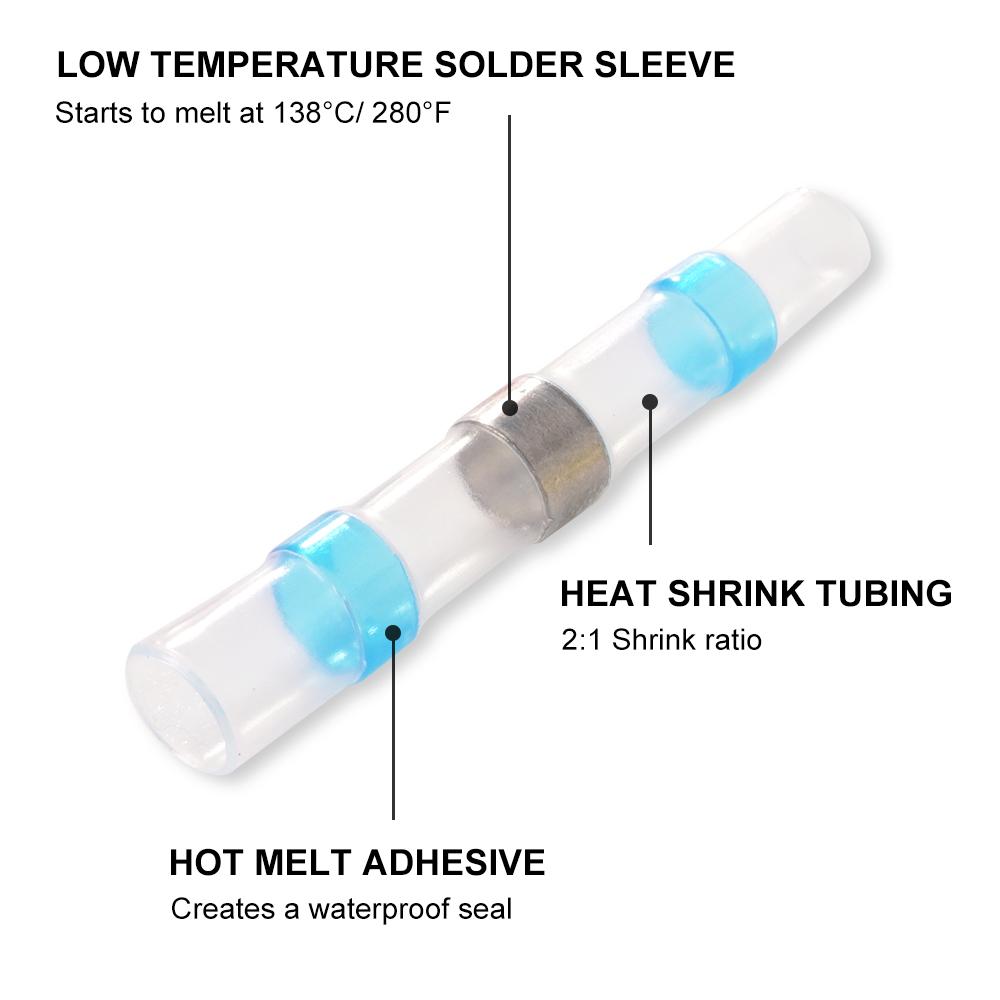

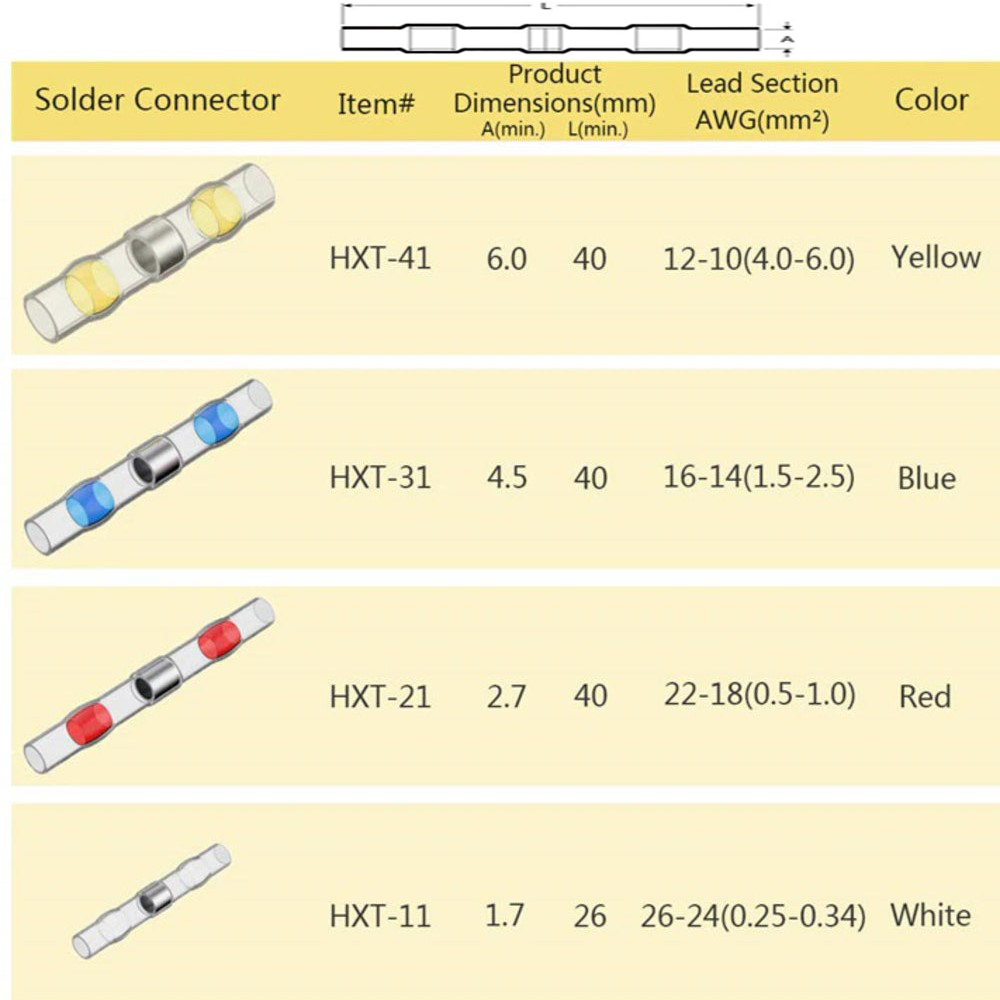

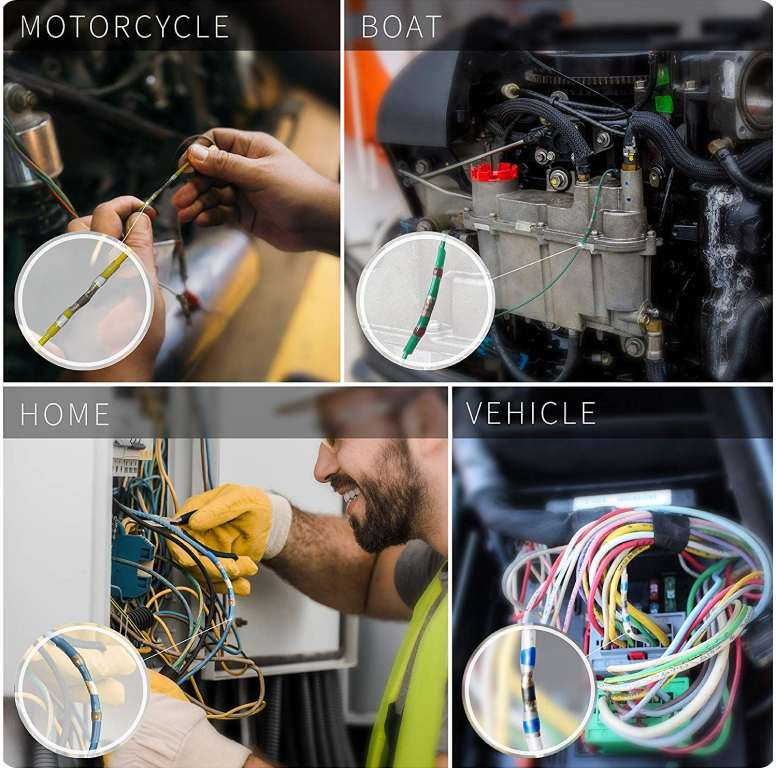

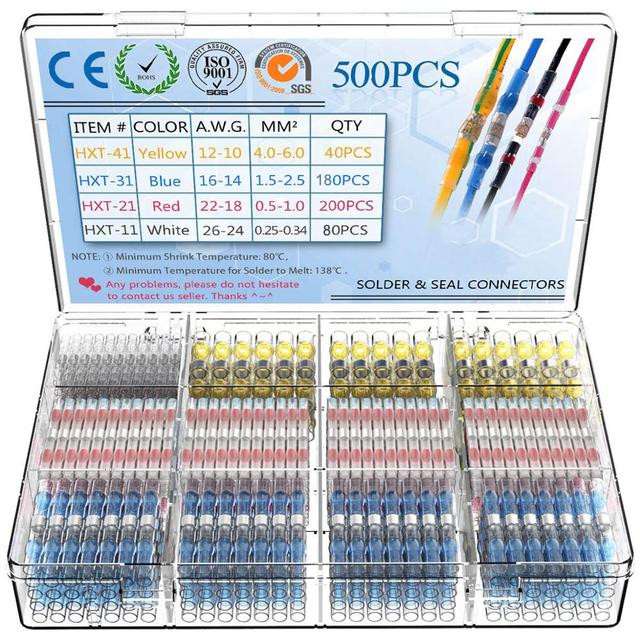

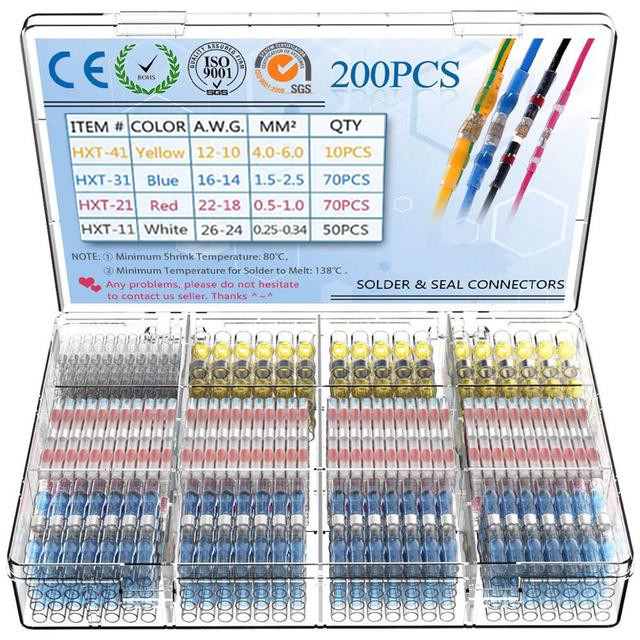

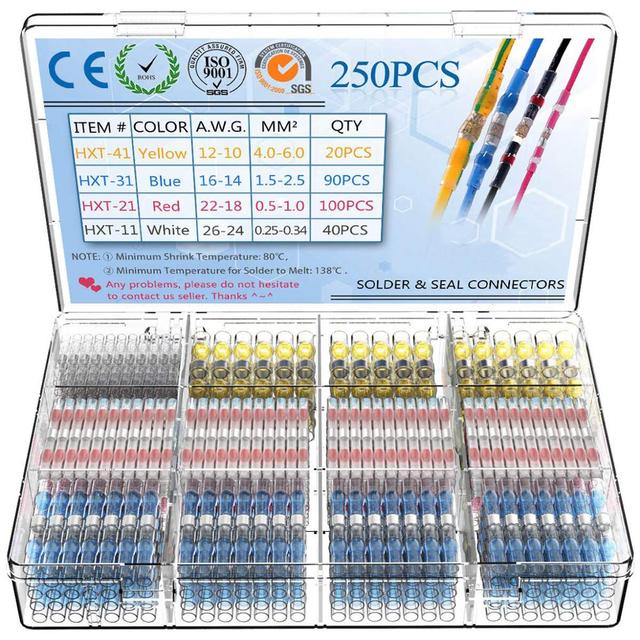

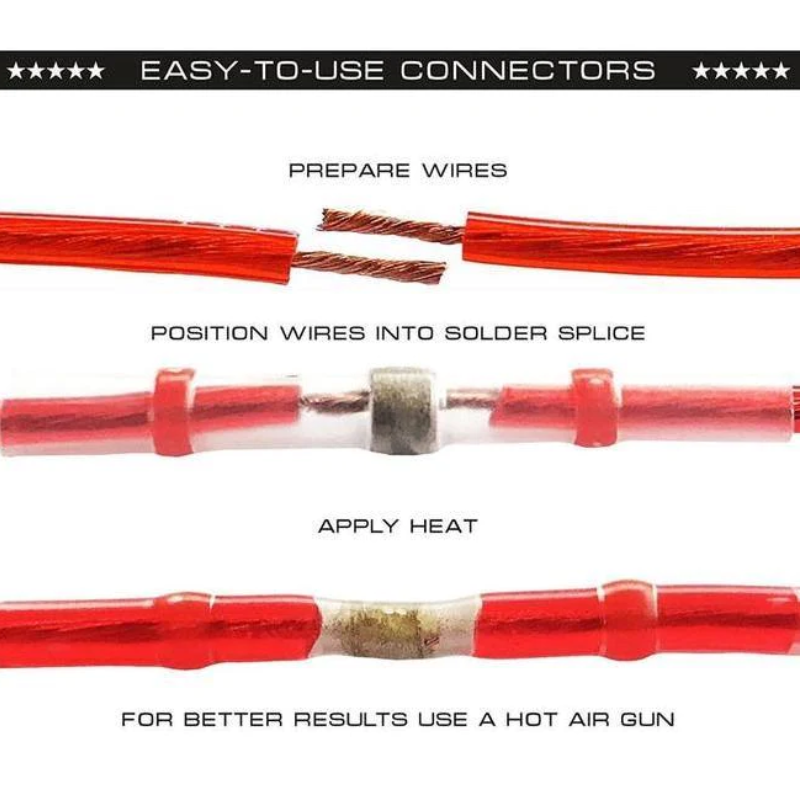

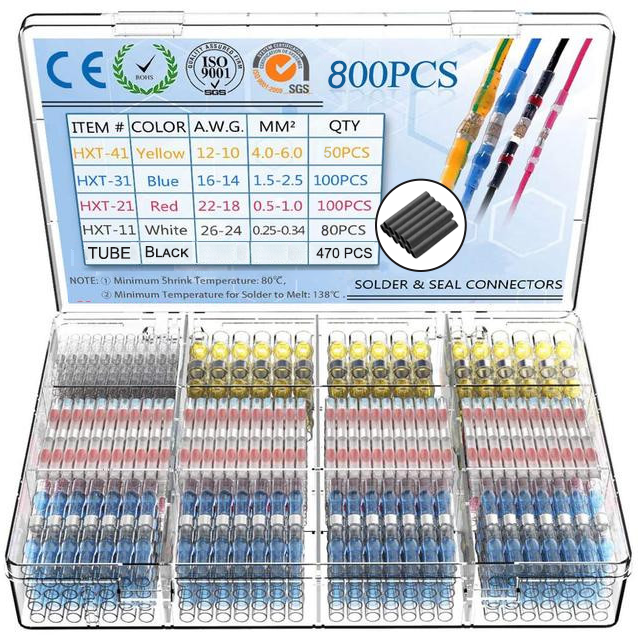

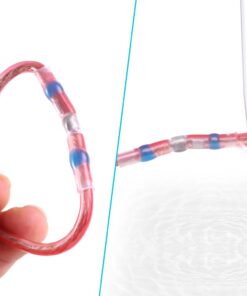

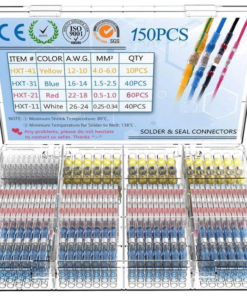

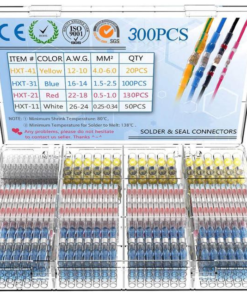

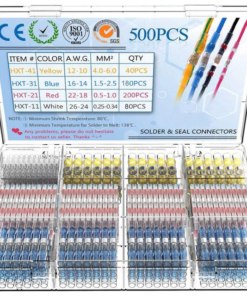

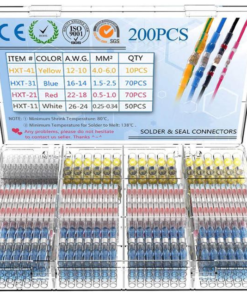

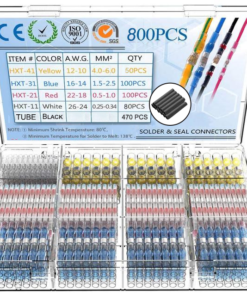

Solder Seal Wire Connectors Heat Shrink Waterproof Electrical Wire Terminals Connectors Kit

$55.99

-

Returns & Exchanges within 30 daysAny return for unsatisfied item(s) is available in 30 days

-

Worry-Free ReturnsSeller covers return shipping

-

Money Back GuaranteeA full refund within one week upon receiving your return

-

3-Month WarrantyCovering any possible defect in materials and workmanship